MyAsensiot Condition Screening®

Complementary Solution Completing the Existing Maintenance Planning and Scheduling for Extensive Coverage of Rotating Assets

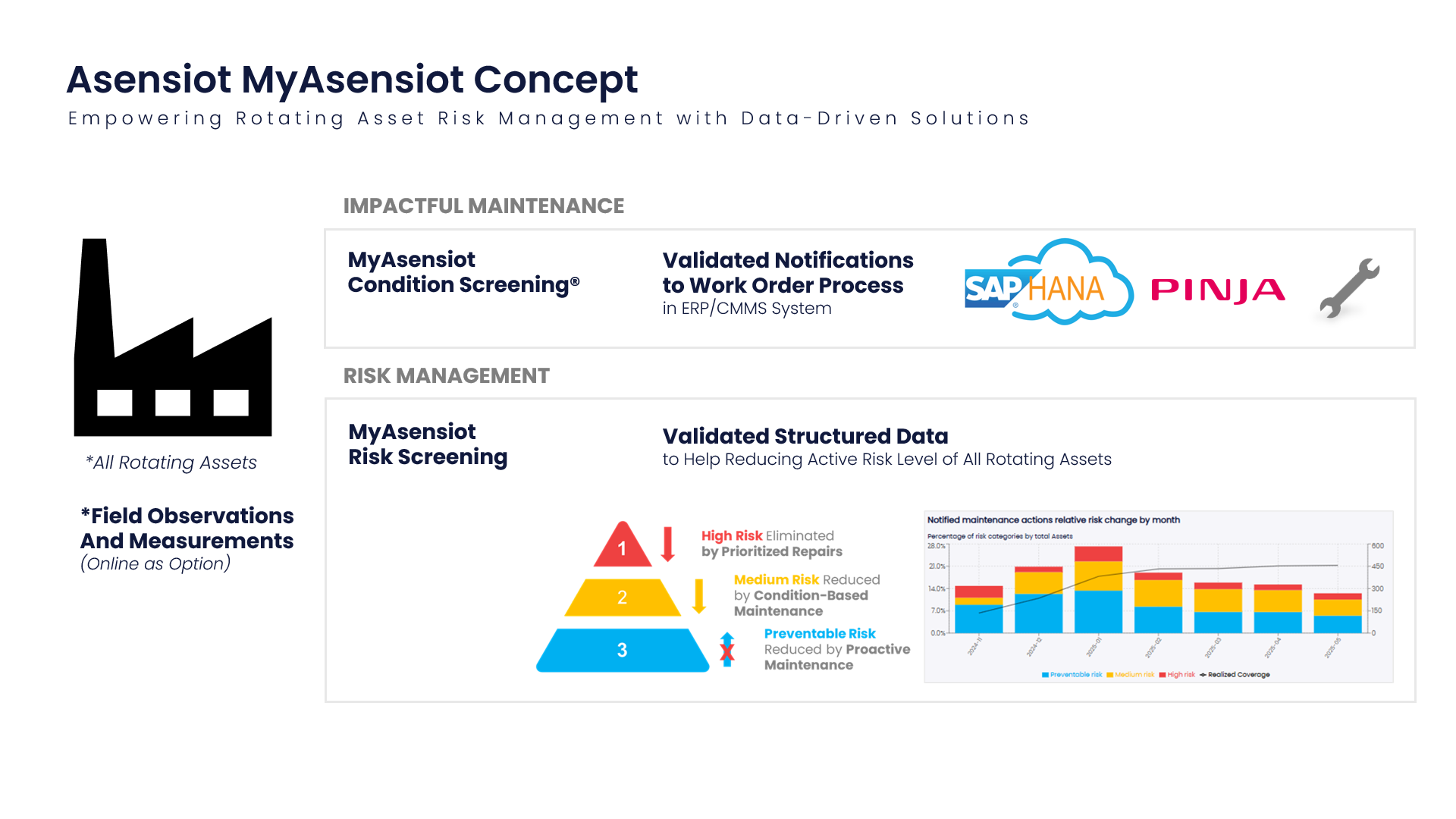

What Asensiot Does?

Asensiot empowers your maintenance teams with intelligent notifications and actionable insights, seamlessly integrating with your work management process. By measuring effectiveness and driving meaningful actions, we help you enhance risk management, boost operational predictability, and optimize planning.

What This Means in Practice?

Traditional preventive maintenance tasks, such as lubricating the bearings of rotating machines, are often carried out as routine activities based on pre-set schedules. Asensiot brings a new perspective by delivering an up-to-date and comprehensive view of preventive maintenance routine effectiveness. It also provides easy-to-understand, actionable information that helps steer maintenance activities precisely to the assets where they have the greatest impact in preventing faults and enhancing machine reliability. This combination of clear insights and targeted guidance empowers teams to optimize maintenance efforts and improve overall asset performance – proactively.

Value as a Service

| VaaS |

Includes everything from implementation to actionable information to Enterprise Resource Planning or CMMS systems via REST API.

One Monthly Fee without Hidden Costs and Transparently

How Asensiot Does It?

1. Structured, Actionable Information for Proactive Maintenance

MyAsensiot provides over 90% of all maintenance information in a structured format, enabling clear, understandable insights for maintenance teams. This approach guides impactful maintenance actions that extend asset lifetime and minimize costly repairs and downtime.

2. Standardized Way of Working with Expert Validation

The platform integrates advanced AI screening with ISO-certified vibration analysts who validate findings. This standardization ensures accuracy and reliability of notifications, leading to effective prioritization and confident decision-making.

3. Seamless Integration with ERP and CMMS Systems

MyAsensiot connects easily to systems like SAP S/4HANA via REST API, enabling automated transfer of actionable alerts into work order systems. This integration supports enterprise-wide scalability and ensures insights translate directly into planned maintenance actions.

4. Clear ROI Through Impactful Maintenance Actions

Through early detection, root cause analysis, and optimized scheduling, MyAsensiot helps avoid unnecessary maintenance and unplanned downtime, resulting in significant cost savings and resource optimization for clients.

5. Scalable Deployment and Sustainable Reliability

The platform’s scalable AI algorithms and standardized processes allow rapid deployment across hundreds of assets with minimal fieldwork. This enables organizations to efficiently scale their reliability programs while supporting environmental sustainability goals by reducing energy use and material waste.

Empowering maintenance teams with trusted, structured data-driven insights in a standardized, scalable way that delivers clear business value and sustainability impact.

High-Performing Preventive Maintenance is the Foundation of Genuinely Sustainable Reliability

It’s somewhat ironic that existing predictive maintenance technologies often focus on supporting maintenance teams to schedule repairs, while preventive maintenance aims to stop faults from progressing but lacks data-driven support for daily decisions. Asensiot empowers you to move beyond unnecessary scheduled repairs by providing clear, actionable insights that help prevent fault progression before it starts, building a more sustainable maintenance approach.

More Than Just Technology

Positive User Feedback

Rapid Deployment: 100+ Assets Integrated in 24 Hours

Intuitive User Experience

Real-World Success Stories Driving Team Engagement

Unlocking Potential with Condition-Based Maintenance

Immediate Results: High-Value Use Cases Identified

Proactive Maintenance Strategies for Enhanced Efficiency

Realiability Communicated Throught Better Risk Management

MyAsensiot Condition Screening® is Registered Trademark

Asensiot’s new approach Improves efficiency and communication between organisations.

Active Risk Status for Production

Maintenance Notifications for Planning and Scheduling

Data-Driven Operations and Digitalization for IT

Our Mission

At Asensiot, we believe that while technological progress is often celebrated, it has also led to a decline in appreciation for traditional preventive maintenance and the valuable tacit expertise behind it. Too often, technology reveals equipment issues only during major repairs, reducing opportunities for early action that could extend asset life and improve cost efficiency.

Our mission is to restore that balance by creating a comprehensive operational overview that supports truly preventive maintenance and guides it toward more effective, insightful, and impactful outcomes.

Bad Actor Scoring

Bad Actors are assets associated with frequent failures and high maintenance costs, negatively impacting business operations. Asensiot’s scoring system helps identify these problematic assets, allowing maintenance planners to focus their efforts where they’re most needed.

Benefits of Effective Asset Prioritization

RESOURCE ALLOCATION

DOWNTIME REDUCTION

COST OPTIMIZATION

PERFORMANCE IMPROVEMENTS

Only an Impactful Maintenance Action

Leads to Value

Why Asensiot is Connected to SAP S/4 HANA PM Module?

In Asensiot, we feel responsibility for the environment and society. That’s how we understand SUSTAINABILITY – one of our core values.

By focusing on the impactful maintenance actions – that improve asset uptime while minimizing the environmental impact, resources, and costs – has positive impact for sustainability. The bigger amount of machines under the scope, the bigger is the impact.

SAP is an essential source for the maintenance asset data and through connection between SAP and Asensiot we ensure that results are put into action using company wide ERP solution.

Connectivity to SAP also enables larger scale data and analytics possibilities for companies within maintenance area.

Sustainability is the result of impact and scale. Machine Reliability goes hand in hand with companies’ culture and best practices. We help customers along their reliability journey – That’s what Asensiot’s Sustainable Reliability is all about.

MyAsensiot Condition Screening® has easy connectivity to any Maintenance Planning System with its REST API.

Supporting Client's Sustainable Maintenance Goals

“Asensiot's new VaaS concept supports Kemira adopting a Sustainable Reliability approach to asset. Kemira can achieve multiple benefits, including increased equipment uptime, reduced maintenance costs, decreased manpower requirement, improved energy efficiency, and a smaller ecological footprint.”

Carl Bristow, Kemira

Sr.Manager, Manufacturing/Operational

Excellence & Sustainability

Sustainability is Our Shared Responsibility

The Maintenance Goals are Achievable

"Implementing the MyAsensiot solution has enabled a more proactive approach to our asset maintenance helping us to reduce unwanted failures. Visual inspection of rotating asset during monthly measurement rounds is a key factor in assessing the condition of the asset. The MyAsensiot solution is also used in the planning of maintenance revisions, ensuring that maintenance actions are only targeted at those assets that require maintenance. This optimizes the use of resources and reduces unnecessary maintenance actions."

Riku Rantanen, Kemira

PP EMEA Regional Maintenance Cluster Manager

MyAsensiot Validation Process is not a Mystery

Maintenance Action Decision-Making Process

The end client retains full control over scheduling, declining, or completing maintenance actions. MyAsensiot’s actionable information supports data-driven decision-making in this process.

Work Order Notification Categories

Non-Routine Actions

Require attention before the next monthly routine

Examples:

Repairs

Friction or load reductions

Intensified measurements

Routine Actions

Monthly measurement and observation routines performed in the field

No Actions Required

Asset condition is deemed acceptable

Impactful Maintenance

Recent maintenance actions have positively impacted asset condition

Fault Progression

Asset condition shows continuous deterioration

This streamlined categorization system enables efficient prioritization and management of maintenance tasks, ensuring timely responses to critical issues while optimizing resource allocation.

The Success is Active Collaboration.

We Create New Maintenance Rock Stars

The Stage is Yours!

ASENSIOT NEWS 2025

Follow us on LinkedIn , where we regularly share customer experiences and success stories.

- 15.8.2025

Ambientia Group strengthens its expertise in industrial digitalization

Ambientia Group is strengthening its expertise in industrial digitalization and data-driven management by acquiring a majority stake in its long-time partner Asensiot Oy. Asensiot will continue to operate as an independent subsidiary under its own brand with its core team, while gaining access to Ambientia’s broad expertise and resources—enabling even more effective solutions for customers.

Ambientia and Asensiot will, through the transaction, be able to offer an even more comprehensive service portfolio in industrial digitalization and maintenance. Asensiot brings deep expertise in maintenance for the process industry and a direct route to a rapidly growing international market, while Ambientia’s wide customer base and resources create an opportunity to expand the availability of services into new markets.

Ambientia and Asensiot have worked together for several years on developing the MyAsensiot Condition Screening® service, which enables genuinely data driven proactive maintenance and risk management in the process industry. The service has already reduced unnecessary maintenance activities and extended equipment lifetimes in several industries, ensuring reliable and cost-effective operations.

“We have long enjoyed fruitful collaboration with Asensiot in product development and with shared customers. I’m very excited that we can now welcome Asensiot into the Ambientia family. Asensiot’s expertise, service offering and customer market align extremely well with Ambientia’s new growth strategy. They have succeeded in making it concrete how digitalization and data driven management can produce significant, measurable value for companies,” says Olli Porola, CEO of Ambientia Group.

“We are excited about this new chapter in Asensiot Oy’s history. Joining Ambientia Group allows us to offer a broader range of services and deeper expertise to our customers. We will continue operating under our own name, brand and core team, while gaining additional strength and capabilities to accelerate our growth and open new international market areas through this arrangement,” says Aki Karuveha, Co-founder and Chief Business Officer of Asensiot Oy.

Asensiot’s integration into Ambientia Group provides customers with an even wider set of solutions that enhance business efficiency. By combining our expertise, we can offer and customize maintenance and risk management solutions that deliver measurable value and support our customers’ long-term success.

From Healthcare to Industrial Care: Kemira’s Revolutionary Approach to Asset Management

- 10.6.2025

Just as modern healthcare has shifted from treating illnesses to preventing them, Kemira is revolutionizing industrial maintenance by treating its rotating assets like a population of patients. The secret? Treating equipment failure is not as inevitable, but as entirely preventable.

Through an innovative partnership with Asensiot Oy, the global chemical company has developed a groundbreaking preventive approach that’s already delivered a sevenfold return on investment across ten production sites.

Ambientia and Asensiot have worked together for several years on developing the MyAsensiot Condition Screening® service, which enables genuinely data driven proactive maintenance and risk management in the process industry. The service has already reduced unnecessary maintenance activities and extended equipment lifetimes in several industries, ensuring reliable and cost-effective operations.

“In safety, every accident is preventable. Yet, when it comes to rotating assets, we still accept failures as inevitable. Why are we willing to tolerate risks that we know can be eliminated? OEE (Overall Equipment Efficiency) can track performance but misses hidden risks, so we needed new metrics in risk assessment,” begins Carl Bristow, Director of Safety & Manufacturing Excellence at Kemira Oyj, a global chemical company.

Kemira operates over 60 production facilities worldwide, but previously lacked a comprehensive, real-time overview of the true condition of its rotating equipment, an essential requirement for enabling a new, more sustainable maintenance strategy.

Traditional condition monitoring practices focus mainly on critical assets, leaving the overall picture of asset health incomplete.

To improve data-driven management, Kemira launched a collaboration project with Asensiot Oy, a Finnish Value-as-a-Service company, in 2021. The goal was to create a new, scalable operating model that would support Kemira’s sustainable maintenance goals, motivate field personnel, and allow for easy and rapid implementation from one plant to another. This approach aimed to quickly identify concrete cases to achieve Kemira’s strategic objectives.

Kemira’s Wave 1 Statistics

• Wave 1: 10 Sites (Results from November 2023 Onward)

• Deployment Time: 14 Days On-Site / 2 Persons

• Measured: 779 Individual Assets

• Extended Asset Lifetime: 14 Realized Cases

• Avoided Unplanned Shutdowns: 45 Realized Cases

• Estimated Costs Avoided: €2,264,000 (~7x ROI)

Kemira’s proactive, data-driven approach to rotating asset risk assessment is delivering tangible benefits across its global operations. By focusing on early detection, actionable insights, and scalable processes, Kemira is setting a new benchmark for sustainable reliability and maintenance excellence in the process industry.